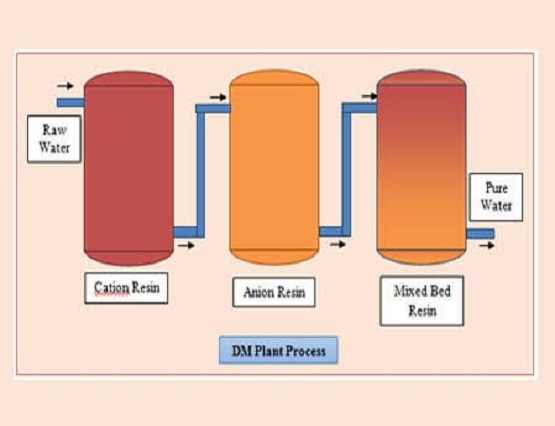

DM & MB Plant

The two-bed deionizer consists of two vessels - one containing a Cation-exchange resin in the hydrogen(H+) form and the other containing an anion resin in the hydroxyl (OH-) form. Water flows through the caution column, whereupon all the captions are exchanged for hydrogen ions.

To keep the water electrically be lanced, for every monovalent Caution, e.g. Na+, one hydrogen ion is exchanged and for every divalent caution, e.g. Ca2+ , or Mg2+, two hydrogen ions are exchanged. The same principle applies when considering anion exchange. The desalinized water then flows through the anion column.

. This time all the negatively changed ions are exchanged for hydroxide ions which then combine with the hydrogen ions to form water (H2O). A mix bed pressure vessels are also added to produce better quality water. Water being used in Foundries, Dairies, Food & Beverages, Brewery, Pharmaceuticals, Plating plants, Paper & Pulp Industry Paint & Ceramic, Rubber & plastics, Tannery & other industries.

Our Specialty

As the seed falls to the ground, it floats along air currents due to its wing